To obtain information about a physical value, a measuring system is needed. This system may consist of a single unit that gives an output or signal according to the magnitude of the unknown variable applied to it, or it can be a complex set-up of elements acting together.

The main element of the measuring system is the sensor, it gives an output that is a function of the measure (the input applied to it). For most but not all sensors, this function is at least approximately linear.

Signal processing elements are used to improve the quality of the output of a measurement system. A very common type of signal processing element is the electronic amplifier, which amplifies the output of the primary transducer or variable conversion element, thus improving the sensitivity and resolution of measurement. This element of a measuring system is particularly important where the primary transducer has a low output.

Some measurement systems may include components to transmit the signal to some remote point and or to display or record it, the main reasons for transmitting the signal are because the observation or application point of the output of a measurement system is some distance away from the site of the primary transducer, for convenience, because of inaccessibility or environmental unsuitability of the site of the primary transducer.

Main characteristics of the Measuring Instruments

Accuracy

The accuracy of an instrument shows how close is the output of an instrument to the real value. In practice, it is common to show the inaccuracy for an instrument. Inaccuracy or measurement uncertainty is the extent to which a reading might be wrong and is often shown as a percentage of the full-scale. It depends on linearity, hysteresis, offset and sensitivity. The resulting discrepancy is stated as a ± deviation from the true value.

Precision

It refers to the limits within a signal can be read. It describes an instrument’s degree of freedom from random errors. Precision is often confused with accuracy. High precision does not imply anything about measurement accuracy. A high-precision instrument may have a low accuracy. Low accuracy measurements from a high-precision instrument are normally caused by a bias in the measurements, which can be corrected by recalibrating the instrument.

Repeatability and Reproducibility

Reproducibility is the ability of an instrument to repeatedly read the same signal over time, and give the same output under the same conditions, it describes the closeness of output readings for the same input when there are changes in the method of measurement, observer, measuring instrument, location, conditions of use, and time of measurement. Repeatability describes the closeness of output readings when the same input is applied repetitively over a short period of time, with the same measurement conditions, same instrument and observer, same location, and same conditions of use maintained throughout.

The degree of repeatability or reproducibility in measurements from an instrument is an alternative way of expressing its precision.

Sensitivity

Sensitivity is the smallest amount of difference in quantity that will change an instrument's reading. High sensitivity in an instrument is preferred as this gives higher output amplitudes, but this may have to be weighted against linearity, range, and accuracy.

Sensitivity to Disturbance

Each instrument is calibrated and specified to function properly only under certain conditions, which are usually defined in the instrument specification. As variations occur in the ambient temperature, certain static instrument characteristics change, and the sensitivity to disturbance is a measure of the magnitude of this change. Such environmental changes affect instruments in two main ways, known as zero drift and sensitivity drift. Zero drift is also called bias.

All sensors are affected by environmental conditions and use over time. The output at zero reading will drift slightly over time. Some types of sensors will exhibit a greater amount of zero drift at the beginning due to settling-in period of the materials used in the construction of the sensor. Other sensors may get worse over time because the sensor performance characteristics have deteriorated due to heavier than normal use over the typical service life of the sensor. Zero drift is normally removable by calibration.

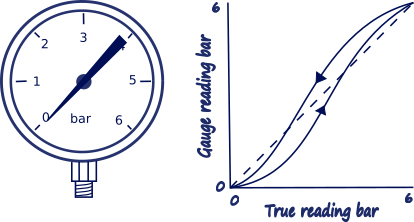

Hysteresis

If an instrument provides a different reading for the same measured values depending on whether measurand is increased or decreased, then the characteristic of this instrument is said to have a hysteresis.

Figure 1. Hysteresis curve of an Instrument.

Resolution

Resolution is the smallest amount of a variable that an instrument can resolve, i.e., the smallest change in a variable to which the instrument will respond. When an instrument is showing a particular output reading, there is a lower limit on the magnitude of the change in the input measured quantity that produces an observable change in the instrument output.

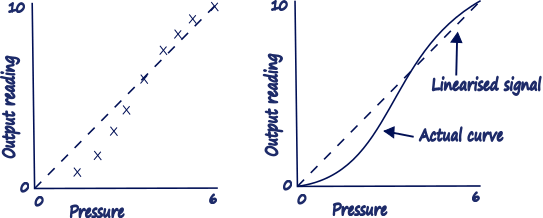

Linearity

Linearity shows how close is a curve to a straight line. It is desired that that the output reading of an instrument is linearly proportional to the quantity being measured. Linearity is a measure of the proportionality between the actual value of a variable being measured and the output of the instrument over its operating range. It expresses the deviation of the actual reading from a straight line. Figure 2 shows the pressure input versus voltage output curve for a pressure to voltage transducer with the best fit linear straight line. The actual curve is not a straight line. Nonlinearity is then defined as the maximum deviation of any of the output readings marked X from this straight line. Nonlinearity is usually expressed as a percentage of full-scale reading. If the response of an instrument is non-linear this may lead to problems in the control system, the signal needs to be linearised.

Figure 2. Instrument output characteristic.

Response

When the output of a device is expressed as a function of time (due to an applied input) the time needed to respond is crucial about the suitability of the device. A slow responding device may not be suitable for an application.

Threshold

If the input to an instrument is increased gradually from zero, the input will have to reach a certain minimum level before the change in the instrument output reading is of a large enough magnitude to be detectable. This minimum level of input is known as the threshold of the instrument. Manufacturers vary in the way that they specify threshold for instruments. Some quote absolute values, whereas others quote threshold as a percentage of full-scale readings.

Range of Operation

The range of operation defines the high and low operating limits between which the device will operate correctly, and at which the other specifications are guaranteed. Operation outside of this range can result in excessive errors, equipment malfunction and even permanent damage or failure.

Instrument types

Active and Passive Instruments

Instruments are divided into active or passive ones according to whether instrument output is produced entirely by the quantity being measured or whether the quantity being measured simply modulates the magnitude of some external power source.

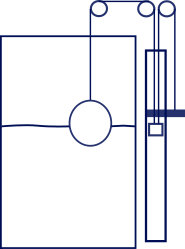

Figure 3 shows an example of passive instrument. The level measuring system is driven by the weighted float, indicator slides freely up and down on the outside of the guide tube balanced by the counterweight within, its position shows the actual level in the tank. No external power source is needed.

Figure 3. Passive level measuring system.

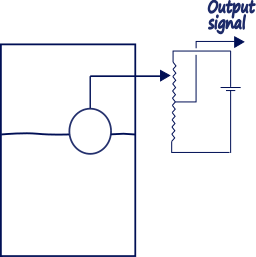

An example of an active instrument is shown in Figure 4. Here the level measurement system uses external energy source. Any level change moves a potentiometer arm, and the output signal consists of a proportion of the external voltage source applied across the two ends of the potentiometer. The energy in the output signal comes from the external power source: the primary transducer float system is merely modulating the value of the voltage from this external power source. In active instruments, the external power source is usually in electrical form, but in some cases, it can be other forms of energy, such as a pneumatic or hydraulic one.

Figure 4. Active level measuring system.

One very important difference between active and passive instruments is the level of measurement resolution that can be obtained. With the simple level gauge shown, the amount of movement made by the pointer for a level change is closely defined by the mechanical characteristics of the instrument. In an active instrument, however, adjustment of the magnitude of the external energy input allows much greater control over measurement resolution.

Analogue and Digital Instruments

An analogue instrument gives an output that varies continuously as the quantity being measured changes. The output can have an infinite number of values within the range that the instrument is designed to measure. A digital instrument has an output that varies in discrete steps and so can only have a finite number of values.

Measurement units

The main measurement systems are the British imperial system and the closely related US customary system use the foot as a measure of length, the pound as a measure for weight, and the second as a measure for time.

The metric system or SI system uses 10, 100 or 1000 of a smaller unit to make a bigger one: For instance, there are 100 centimetres in 1 metre or 1000 grams in 1 kilogram. This system uses the metre for length, the kilogram for weight, and, like the other two systems, the second for time.

As with all disciplines, a set of standards has evolved over the years to ensure consistency and avoid confusion. The Instrument Society of America (ISA) has developed a complete list of symbols for instruments, instrument identification, and process control drawings.

| Quantity | English | SI | ||

|---|---|---|---|---|

|

Base units |

Units |

Symbols |

Units |

Symbols |

|

Length |

Foot |

Ft |

Meter |

m |

|

Mass |

Pound |

Lb |

Kilogram |

kg |

|

Time |

Second |

S |

Second |

S |

|

Temperature |

Rankine |

R |

Kelvin |

K |

|

Electric current |

Ampere |

A |

Ampere |

A |

Table 1. Basic units.

Instrument selection criteria

The main criteria when choosing an appropriate instrument the specification requirements. Parameters such as desired measurement accuracy, resolution, sensitivity, and dynamic performance. Of big importance are also the environmental conditions that the instrument will be subjected to, as some conditions will immediately either eliminate the possibility of using certain types of instruments or the instrument should be protected. Sometimes protection may reduce the performance of the instrument, especially in terms of its dynamic characteristics. The instrument should be, when possible, insensitive to influences from the operating environment.

Generally, the better the characteristics, the higher the cost. However the instrument’s durability, maintainability, and constancy of performance are very important aswell. The instrument chosen will often have to be capable of operating for long periods without performance degradation and a requirement for costly maintenance, once the plant is running every downtime caused by instrument malfunction can be very expensive. In consequence of this, the initial cost of an instrument often has a low weighting in the evaluation exercise.

Cost is correlated very strongly with the performance of an instrument, as measured by its static characteristics. Increasing the accuracy or resolution of an instrument, for example, can only be done at a penalty of increasing its manufacturing cost. As a general rule, a good assessment criterion is obtained if the total purchase cost and estimated maintenance costs of an instrument over its life are divided by the period of its expected life. However, this rule becomes modified where instruments are being installed on a process whose life is expected to be limited, perhaps in the manufacture of a particular model of car. Then, the total costs can only be divided by the period of time that an instrument is expected to be used for, unless an alternative use for the instrument is envisaged at the end of this period.

0 COMMENTS //

Join the discussion