There is a variety of safety switches that help ensure safe working conditions for personnel, machine and environment. These critical components provide high quality and reliability for machines and process applications.

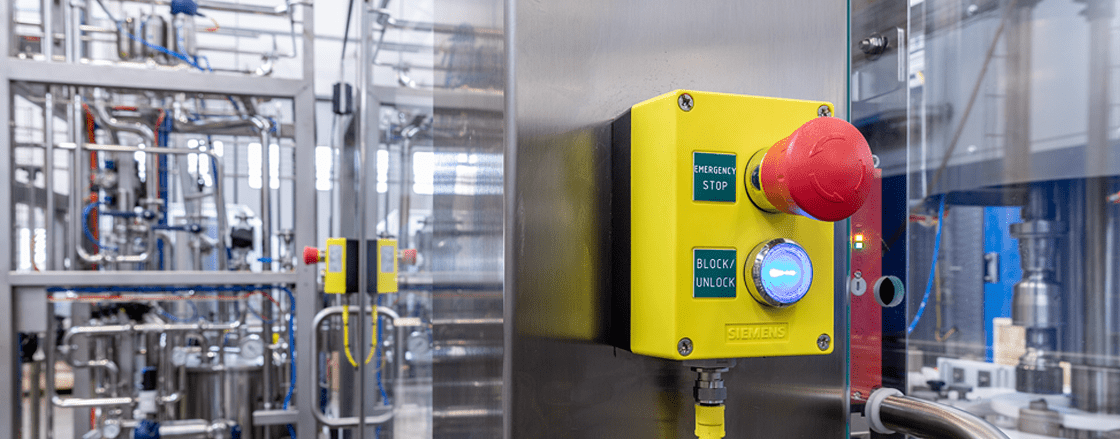

E-Stop switch

E-Stop is a safety mechanism used to shut off machinery in an emergency, when it cannot be shut down in the usual manner. (Source: Wikipedia)

An E-stop switch, otherwise known as an emergency stop switch, is a form of fail-safe control. When utilized, an E-stop switch halts the operation of associated equipment and shuts off all potential hazards outside of the equipment’s main power enclosure.

E-stops are typically integrated into the circuitry of a machine or electrical system so that if they are used, the circuit becomes disconnected and cuts off electrical power to the machine. This makes it physically impossible for the machine to be used until the switch is reset and the system undergoes restart procedures. (Source: Safeopedia)

Image 1. E-Stop button. (Image credit: © Siemens AG 2022, All rights reserved)

Emergency Stop must fulfil specific standard requirements, for example IEC 60204-1.

Also, ISO 13850 describes the characteristics of a E-Stop push button. Which includes a RED mushroom operator head with yellow background. They must also be self-latching, meaning that once actuated the Emergency Stop will remain in the actuated state until a voluntary and deliberate action is performed, such as twisting and/or pulling of the button for reset. In addition, this resetting of the E-Stop alone should not resume operation. Instead, a second deliberate action is needed, such as the pressing of a RESET button which resets safety a relay.

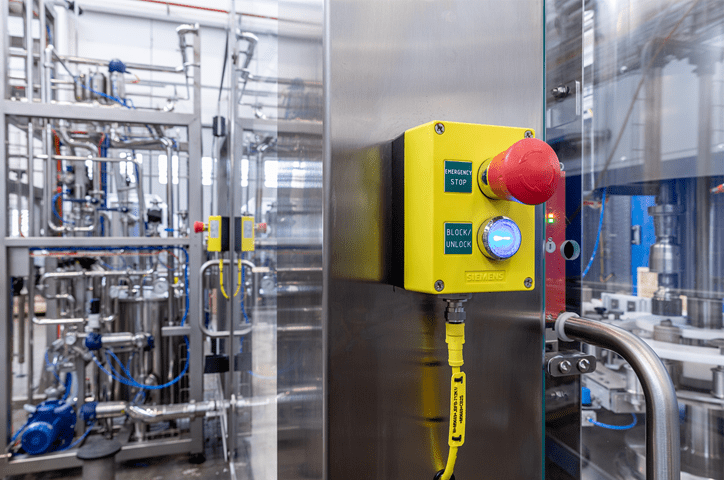

Cable pull switch

If a dangerous situation arises, the operating personnel can put a system into a safe status using rope pull switches. Typical application is the use in longer conveyor systems since the switching function can be triggered from any point along the conveyor system. (Source: SICK)

Image 2. Cable pull switch. (Image credit: © Siemens AG 2022, All rights reserved)

Enabling grip switches

Enabling and grip switches give manual control of the machines while ensuring a safe work environment. Enabling grip switches are safety components used to prevent unexpected machine operation when personnel perform maintenance or other non-routine tasks inside hazardous areas, such as areas inside protective shields, for example use in robot cells during maintenance, troubleshooting, programming and testing.

The enabling grip switches allow the operator to work safely on a machine without disabling operation.

The switches are also known as "3-position safety" switches. The idea behind this type of switches is that the operator must keep a light amount of operating force on the switch during the operation of the application. As soon as the switch is released, the machine operation will stop, keeping the operator away from any danger.

The difference between this type of switch and the other safety switches is the third position. When extra operating force is put on the device by a panicked operator, the switch will also initiate a stop.

When endangered each person acts different, it is possible that a shock would result in either letting go of the device or causing the body to tense up and grip the device harder. Both will initiate a stop command and could prevent loss of life, injury or machine damage.

Read more

Emergency Stop & Emergency switch off

0 COMMENTS //

Join the discussion