The wind is used as a source of energy since ancient times in the ship sailing, windmills for pumping water or grinding flour. A wind turbine is a device that converts the wind's kinetic energy into electrical energy.

The wind energy is used as a source of energy since ancient times in the ship sailing, windmills for pumping water or grinding flour. A wind turbine is a device that converts the wind's kinetic energy into electrical energy.

Types

Modern wind turbines fall into two basic groups: the horizontal-axis HAWT and the vertical-axis design VAWT. Horizontal-axis wind turbines typically either have two or three blades. These three-bladed wind turbines are operated "upwind," with the blades facing into the wind. Small sized turbines can be used in applications such as battery charging for auxiliary power for boats or caravans or to power traffic warning signs. Slightly larger turbines can be used as additional power source in the household. Arrays of large turbines, known as wind farms, are becoming an increasingly important source of renewable energy and are used by many countries as part of a strategy to reduce their reliance on fossil fuels, as the wind has the "lowest relative greenhouse gas emissions, the least water consumption demands" compared to photovoltaic, hydro, geothermal, coal and gas.

VAWT are used less frequently as they are not as effective as HAWT. The Vertical Axis Wind Turbines may be Helical, H-Type, Darrieus, Savonius.

Figure 1. Savonius rotor wind turbine.

Figure 2. Helical rotor wind turbine.

Figure 3. Horizontal rotor wind turbine.

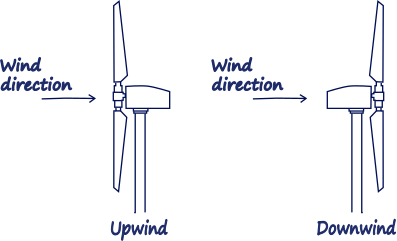

- Upwind.

- Downwind.

The basic drawback of upwind designs is that the rotor needs to be made rather inflexible and placed at some distance from the tower. In addition an upwind turbine needs a yaw mechanism to keep the rotor facing the wind. The extended nacelle that is required to position the rotor far enough away from the tower to avoid any problems with a blade strike. The blades themselves must be somewhat stiff to avoid bending back into the tower. This will mean the point where the blade attaches to the rotor hub will be stressed during high, gusty wind conditions.

Downwind turbines have the rotor placed on the lee side of the tower. They have the theoretical advantage that they may be built without a yaw mechanism, if the rotor and nacelle have a suitable design that makes the nacelle follow the wind passively. The rotor blades can be flexible since there is no danger of a tower strike, so they can be less expensive to make and they can relieve stress on the tower during high wind speed. The basic advantage of the downwind machine is that it may be built somewhat lighter than an upwind machine.

Another advantage of the downwind configuration is that it is easier to take advantage of centrifugal forces to reduce the blade root flap bending moments. This is because the blades are normally coned downwind, so centrifugal moments tend to counteract moments due to thrust.

The basic drawback is the fluctuation in the wind power due to the rotor passing through the wind shade of the tower. This may give more fatigue loads on the turbine than with an upwind design. The effects of the tower shadow may to some extent be reduced by utilizing a tower design which provides minimal obstruction to the flow. Down-wind turbines noisier (additional aerodynamic noise), and the blades are subject to more forces than those of up-wind turbines. Another serious disadvantage of a down-wind turbine is wind shadow behind the mast causing a drop in power each time a blade passed behind the mast.

Figure 4. Upwind and Downwind orientation.

Locating wind farms

An ideal location would have a near constant flow of non-turbulent wind throughout the year, with a minimum likelihood of sudden powerful bursts of wind. An important factor of wind farm location is also access to local demand or transmission capacity.

There are two types of wind farm locations: Onshore and Offshore.

Onshore turbine installations in hilly or mountainous regions tend to be on ridgelines generally three kilometers or more inland from the nearest shoreline. This is done to exploit the topographic acceleration as the wind accelerates over a ridge. The additional wind speeds gained in this way can increase energy produced because more wind goes through the turbines. The exact position of each turbine matters, because a difference of 30m could potentially double output. This careful placement is referred to as 'micro-siting'.

Offshore wind turbines are less obtrusive than turbines on land, as their apparent size and noise is mitigated by distance. Because water has less surface roughness than land (especially deeper water), the average wind speed is usually considerably higher over open water.

Main construction components of wind turbines

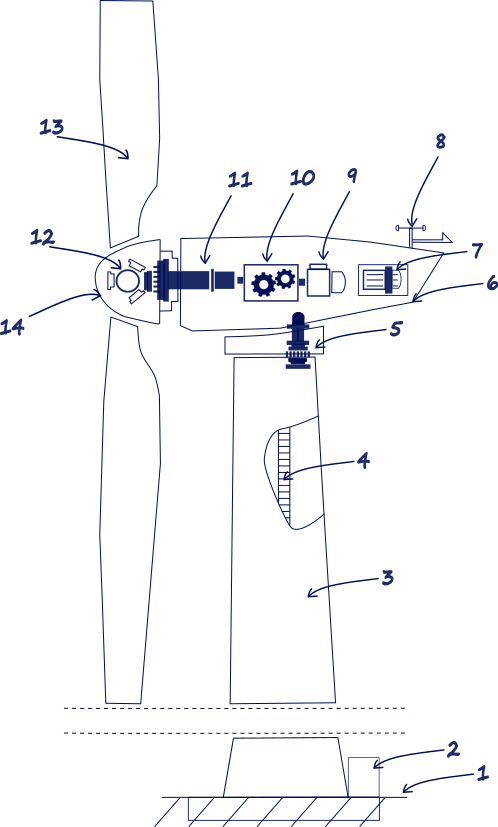

Figure 5. Main components of Horizontal Axis Wind Turbine HAWT.

- Foundation.

- Connection to the electrical grid.

- Tower.

- Access ladder.

- Wind oriented control (Yaw control).

- Nacelle.

- Generator.

- Anemometer and wind vane.

- Braking system.

- Gearbox.

- Main shaft.

- Rotor hub.

- Rotor blades.

- Pitch system.

Wind turbine components in detail

Foundation

The foundation design is always site-specific in that it needs to be designed for the prevailing local soil conditions.

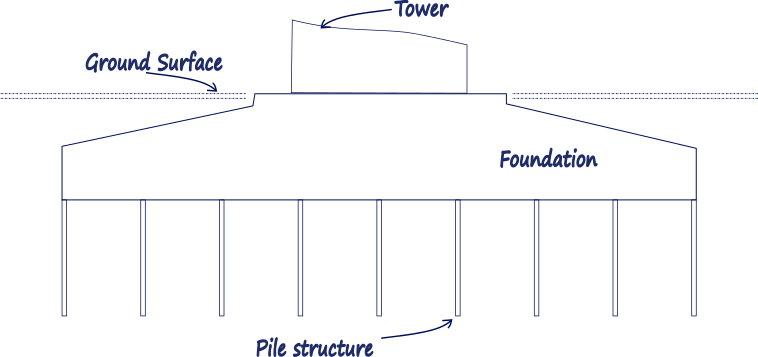

Figure 6. Offshore wind turbine foundation.

Figure 7. Onshore wind turbine foundation.

The current practice for onshore wind turbine foundations is to use massive cast-in-place concrete spread footings or complex pile-supported foundations. Wind turbine generator components and the towers that support them are pre-fabricated and then assembled on site, leaving the foundation as the only component of the wind turbine system requiring major on site construction. There are a lot of factors, like soil type, turbine height, to be considered when designing the foundation.

The offshore foundations may be Bottom Fixed or Floating.

By the floating foundation the tower is held fest with the help of anchors attached to the bottom of the water basin.

The bottom fixed foundation may be:

- Monopile

- Tripod.

- Space frame (Jacket).

- Gravity Based Foundation (GBF).

Usually, the choice of the structure depends on the water depth and the sea bed (rock, sand…)

- Monopile typically until 20/30m.

- Tripod typically until 30/40m.

- Space frame (Jacket) 50/60m.

- Gravity Based Foundation 30/50m.

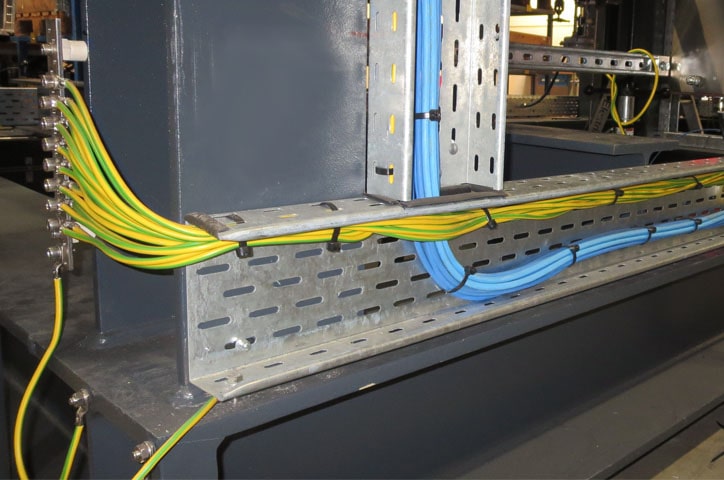

Connection to the electrical grid

The energy generated runs through the inside of the tower to the base. From there, the energy runs over an underground line to the substation, where its voltage is raised in order to inject it into the electrical grid and distribute it to the points of consumption.

Tower and access ladder

The tower of the wind turbine carries the nacelle and the rotor. Towers for large wind turbines may be either tubular steel towers, lattice towers, or concrete towers. Guyed tubular towers are only used for small wind turbines.

Most large wind turbines are delivered with tubular steel towers, which are manufactured in sections of 20-30 meters with flanges at either end, and bolted together on the site. The towers are conical (i.e. with their diameter increasing towards the base) in order to increase their strength and to save materials at the same time.

Lattice towers are manufactured using welded steel profiles. The basic advantage of lattice towers is cost, since a lattice tower requires less material as a freely standing tubular tower with a similar stiffness.

Many small wind turbines are built with narrow pole towers supported by guy wires. The advantage is weight savings, and thus cost. The disadvantages are difficult access around the towers which make them less suitable in farm areas.

Figure 9. Inside view and access ladder in tubular steel tower.

Wind oriented control (Yaw control)

The wind turbine yaw mechanism is used to turn the wind turbine rotor against the wind. A mechanism, which uses electric motors and gearboxes, is implemented to keep the turbine yawed against the wind. The yaw mechanism is activated by electronic controller which several times per second checks the position of the wind vane on the turbine, whenever the turbine is running.

Nacelle

The nacelle contains the key components of the wind turbine, including the gearbox, and the electrical generator. Service personnel may enter the nacelle from the tower of the turbine.

Generation

The gearbox transfers the energy from the rotating blades through a fast axis that is connected to the generator, which produces the electricity.

Anemometer and wind vane. System for automatic orientation.

The anemometer and the wind wane are used to measure the speed and the direction of the wind. The electronic signals from the anemometer are used by the wind turbine's electronic controller to start the wind turbine when the wind speed has reached certain limit and stops it if the wind speed is too high in order to protect the turbine and its surroundings. The wind vane signals are used by the wind turbine's electronic controller to turn the wind turbine against the wind, using the yaw mechanism. The wind turbine is automatically oriented to take maximum advantage of the kinetic energy of the wind, from the data registered by the vane and anemometer that are installed at the top.

Braking system

Some wind turbines have braking system to halt in case of strong winds to protect the rotor and blades from damage. Rotor brakes control over speed, and provide parking and emergency braking.

Gearbox

The low speed shaft of the wind turbine connects the rotor hub to the gearbox. On a modern 1000 kW wind turbine the rotor rotates relatively slowly, about 19 to 30 revolutions per minute (RPM). The slow axis is connected to a gear box that lifts the turning velocity from 13 to 1500 revolutions per minute.

Main shaft

The high speed shaft rotates with approximately 1500 revolutions per minute (RPM) and drives the electrical generator. It is equipped with an emergency mechanical disc brake. The mechanical brake is used in case of failure of the aerodynamic brake, or when the turbine is being serviced.

Rotor hub

Blades and hub together form the rotor. The hub of the rotor is attached to the low speed shaft of the wind turbine.

Blades

The number of blades in the turbine rotor and its rotational speed must be optimized to extract the maximum energy from the available wind.

While using rotors with multiple blades should capture more wind energy, there is a practical limit to the number of blades which can be used because each blade of a spinning rotor leaves turbulence in its wake and this reduces the amount of energy which the following blade can extract from the wind. This same turbulence effect also limits the possible rotor speeds because a high speed rotor does not provide enough time for the air flow to settle after the passage of a blade before the next blade comes along.

There is also a lower limit to both the number of blades and the rotor speed. With too few rotor blades, or a slow turning rotor, most of the wind will pass undisturbed through the gap between the blades reducing the potential for capturing the wind energy. The fewer the number of blades, the faster the wind turbine rotor needs to turn to extract maximum power from the wind.

Turning of the blades. The wind makes the blades turn, which start to move with wind speeds of around 3.5 m/s and provide maximum power with a wind speed 11 m/s. With very strong winds (25 m/s), the blades are feathered and the wind turbine slows down in order to prevent excessive voltages.

Pitch system

On a pitch controlled wind turbine the turbine's electronic controller checks the power output of the turbine several times per second. When the power output becomes too high, it sends an order to the blade pitch mechanism which immediately pitches (turns) the rotor blades slightly out of the wind. Conversely, the blades are turned back into the wind whenever the wind drops again.

The Pitch system is either hydraulic or electric. A number of smaller or older wind turbines do not have a pitch system and rely on the aerodynamical properties of the blades (called stall effect) to achieve the same function.

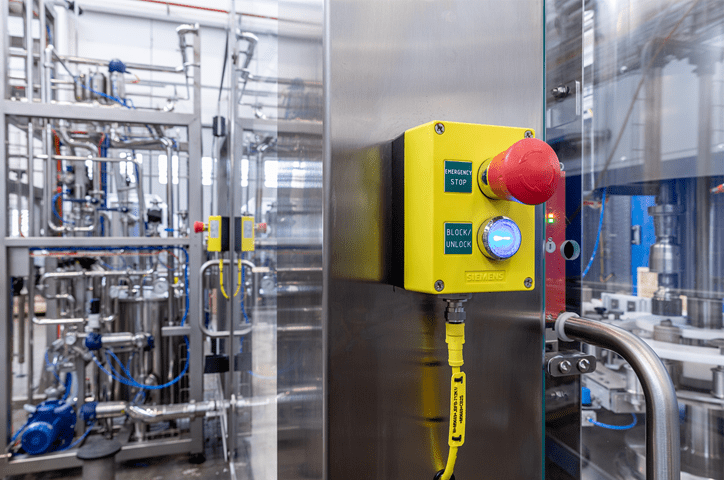

Monitoring

All of the critical functions of the wind turbine are monitored and supervised from the substation and the control center in order to detect and resolve any incidents.

Horizontal Axis Wind Turbines (HAWT)

Horizontal axis wind turbines are the common style of a wind turbine. A HAWT has a similar design to a windmill, it has blades that look like a propeller that spin on the horizontal axis.

Horizontal axis wind turbines have the main rotor shaft and electrical generator at the top of a tower, and they must be pointed into the wind. Small turbines are pointed by a simple wind vane placed square with the rotor (blades), while large turbines generally use a wind sensor coupled with a servo motor to turn the turbine into the wind. Most large wind turbines have a gearbox, which turns the slow rotation of the rotor into a faster rotation that is more suitable to drive an electrical generator.

Since a tower produces turbulence behind it, the turbine is usually pointed upwind of the tower. Wind turbine blades are made stiff to prevent the blades from being pushed into the tower by high winds. Additionally, the blades are placed a considerable distance in front of the tower and are sometimes tilted up a small amount.

Downwind machines have been built, despite the problem of turbulence, because they don’t need an additional mechanism for keeping them in line with the wind. Additionally, in high winds the blades can be allowed to bend which reduces their swept area and thus their wind resistance. Since turbulence leads to fatigue failures, and reliability is so important, most HAWTs are upwind machines.

HAWT Advantages

The tall tower base allows access to stronger wind in sites with wind shear. In some wind shear sites, every ten meters up the wind speed can increase by 20% and the power output by 34%.

High efficiency, since the blades always move perpendicularly to the wind, receiving power through the whole rotation. In contrast, all vertical axis wind turbines, and most proposed airborne wind turbine designs, involve various types of reciprocating actions, requiring airfoil surfaces to backtrack against the wind for part of the cycle. Backtracking against the wind leads to inherently lower efficiency.

HAWT Disadvantages

- Massive tower construction is required to support the heavy blades, gearbox, and generator.

- Components of a horizontal axis wind turbine (gearbox, rotor shaft and brake assembly) being lifted into position.

- Their height makes them obtrusively visible across large areas, disrupting the appearance of the landscape and sometimes creating local opposition.

- Downwind variants suffer from fatigue and structural failure caused by turbulence when a blade passes through the tower’s wind shadow (for this reason, the majority of HAWTs use an upwind design, with the rotor facing the wind in front of the tower).

- HAWTs require an additional yaw control mechanism to turn the blades toward the wind.

- HAWTs generally require a braking or yawing device in high winds to stop the turbine from spinning and destroying or damaging itself.

- Cyclic Stresses & Vibration – When the turbine turns to face the wind, the rotating blades act like a gyroscope. As it pivots, gyroscopic precession tries to twist the turbine into a forward or backward somersault. For each blade on a wind generator’s turbine, force is at a minimum when the blade is horizontal and at a maximum when the blade is vertical. This cyclic twisting can quickly fatigue and crack the blade roots, hub and axle of the turbines.

Vertical Axis Wind Turbines (VAWT)

Horizontal axis wind turbines are typically more efficient at converting wind energy into electricity than vertical axis wind turbines. For this reason they have become dominant in the commercial utility-scale wind power market. However, small vertical axis wind turbines are more suited to urban areas as they have a low noise level and because of the reduced risk associated with their slower rates of rotation.

Vertical axis wind turbines have the main rotor shaft arranged vertically. The main advantage of this arrangement is that the wind turbine does not need to be pointed into the wind. This is an advantage on sites where the wind direction is highly variable or has turbulent winds.

With a vertical axis, the generator and other primary components can be placed near the ground, so the tower does not need to support it, also makes maintenance easier. The main drawback of a VAWT is it generally creates drag when rotating into the wind.

It is difficult to mount vertical-axis turbines on towers, meaning they are often installed nearer to the base on which they rest, such as the ground or a building rooftop. The wind speed is slower at a lower altitude, so less wind energy is available for a given size turbine. Air flow near the ground and other objects can create turbulent flow, which can introduce issues of vibration, including noise and bearing wear which may increase the maintenance or shorten its service life. However, when a turbine is mounted on a rooftop, the building generally redirects wind over the roof, thus doubling the wind speed at the turbine. If the height of the rooftop mounted turbine tower is approximately 50% of the building height, this is near the optimum for maximum wind energy and minimum wind turbulence.

VAWT Advantages

- They can produce electricity in any wind direction.

- Strong supporting tower in not needed because generator, gearbox and other components are placed on the ground.

- Low production cost as compared to horizontal axis wind turbines.

- As there is no need of pointing turbine in wind direction to be efficient so yaw drive and pitch mechanism is not needed.

- Easy installation as compared to other wind turbine. Easy to transport from one place to other.

- Low maintenance costs.

- They can be installed in urban areas.

- Low risk for human and birds because blades moves at relatively low speeds.

- They are particularly suitable for areas with extreme weather conditions, like in the mountains where they can supply electricity to mountain huts.

VAWT Disadvantages

- As only one blade of the wind turbine works at a time, efficiency is very low compared to HAWT.

- Some designs are not self-starting. They need an initial push to start; this initial push that to make the blades start spinning on their own must be started by a small motor.

- When compared to horizontal axis wind turbines they are very less efficient because of the additional drag created when their blades rotate.

- They have relative high vibration because the air flow near the ground creates turbulent flow.

- Because of vibration, bearing wear increases which results in the increase of maintenance costs.

- They can create noise pollution.

- VAWTs may need guy wires to hold it up (guy wires are impractical and heavy in farm areas).

0 COMMENTS //

Join the discussion