The best way to ensure uninterrupted operation in critical environment is to use a dual-VFD system. The typical configuration is two VFDs in a single control cabinet.

The best way to ensure uninterrupted operation in critical environment is to use a dual-VFD system. The typical configuration is two VFDs in a single control cabinet.

In case one VFD fails, a redundant system automatically transfers motor control to the other VFD. The system determines and controls the proper motor speed. Operation proceeds with no noticeable effect on the controlled environment.

Originally introduced as an efficient and effective way to reduce energy consumption by allowing motors to be run at different speeds, variable frequency drives (VFDs) have become common in the industry. While there is no question that VFD technology helps save energy, unfortunately it was somewhat unreliable in the early years and so a solution was needed to keep the system running in case of VFD failure.

The VFD bypass was introduced to ease concerns around reliability, and it played a significant role in the rise of VFD usage. A bypass acts as a backup system to ensure equipment stays operational when or if a VFD fails. A bypass is essentially a motor starter that is built around the VFD to maintain full voltage (across the line) control of the application. The backup allows the application to run at full speed until the problem with the VFD is resolved.

There are two main types of bypass Traditional and Smart bypass

Traditional bypass

The bypass contactor electrically isolates the VFD during bypass operation and is mechanically and electrically interlocked with the bypass contactor to ensure that both cannot be closed at the same time. Most traditional bypasses default to “manual” operation to engage the bypass, someone must manually turn on the bypass in the event that the VFD fails. A VFD fault relay can be used to start the bypass automatically based on a VFD fault, but only if the VFD is not damaged.

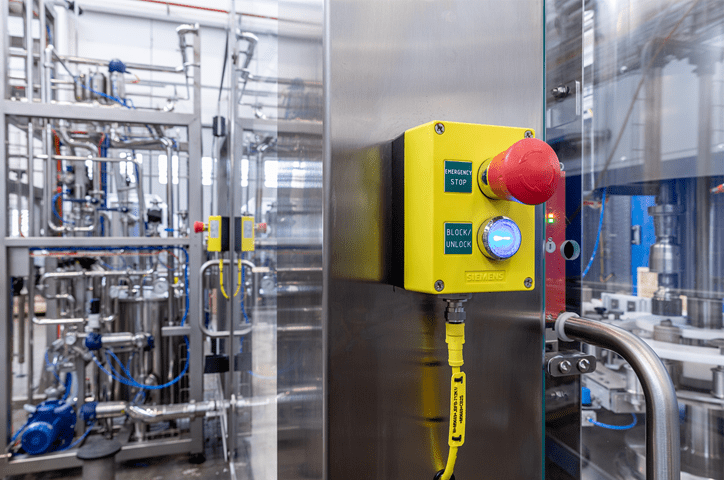

Figure 1. VFD Bypass.

Smart bypass

This microprocessor-based bypass offers advanced features such as protection from phase loss, ground fault, over/undervoltage, and over/under power. These protection features go far beyond what a traditional thermal overload provides. The electronic bypass allows users to select certain conditions in which they want the bypass to start automatically

Redundant Variable Frequency Drives

They work on the principle that if one VFD fails, full control and protection are maintained by a second VFD that automatically takes over. Redundant VFDs are not a new concept; the idea has been around for years, but only recently has this concept become cost-effective. With the VFD market becoming more and more competitive, it’s only a matter of time before bypasses fade away as a viable choice, and dual VFD systems become the standard for critical applications.

These packages require a level of customization because they consist of more than just two VFDs. Both VFDs are identically programmed and the system does not lose any control or protection functionality no matter which VFD is active. To maintain true redundancy, extra power and control circuitry must be added. The standby VFD must be isolated from power while the primary VFD is running to ensure both primary and backup VFDs aren’t damaged in the event of a power surge or spike. To isolate the VFDs, mechanically interlocked input contactors should be added. Back up VFD should be periodically powered up. VFD DC bus capacitors have a shelf life and can degrade without periodic charge cycles. The control system should provide scheduled alternation or charge cycles for standby VFD. The downside of the added power and control components is unfortunately an additional cost.

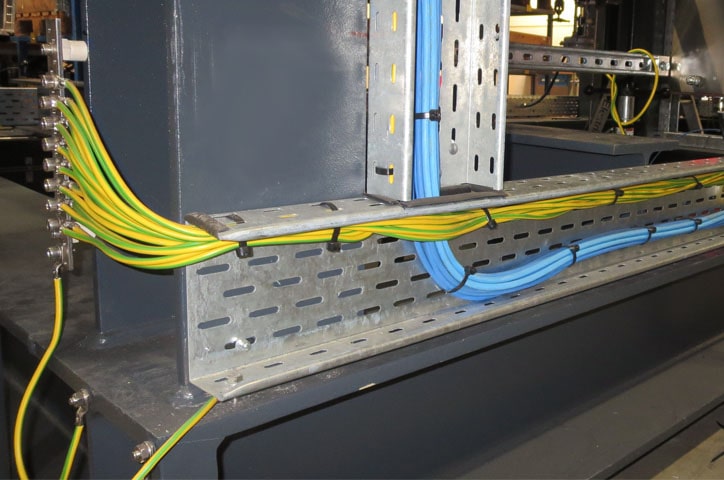

Figure 2. Redundand VFDs

Redundant VFDs include full redundancy, full control with backup VFD, and advanced motor protection all the time. They provide consistent energy savings. However, they are more expensive than traditional and electronic bypasses and more space in electrical cabinet is needed.

Related articles

Variable Frequency Drives (VFD) Part 1 - Wiring

Variable Frequency Drives (VFD) Part 2 - Commissioning

0 COMMENTS //

Join the discussion